Precision Engineering for

HVAC & Ventilation

Over 30 years of manufacturing excellence delivering integrated production lines and heavy-duty machinery for duct pipe and cylinder fabrication to global markets.

30+

Years Experience

100%

B2B Focus

6+

Global Regions

Trusted by Global Partners

Working with leading manufacturers and distributors worldwide

End-to-End Industrial Services

Beyond machinery supply, we provide comprehensive support throughout your production journey.

Custom Engineering

Tailored production line design based on your specific material requirements and factory layout.

Installation & Training

Complete on-site installation services with comprehensive operator training programs.

Technical Support

24/7 remote support and regular maintenance services to ensure optimal performance.

Global Logistics

Worldwide shipping and customs clearance with over 20 years of international export experience.

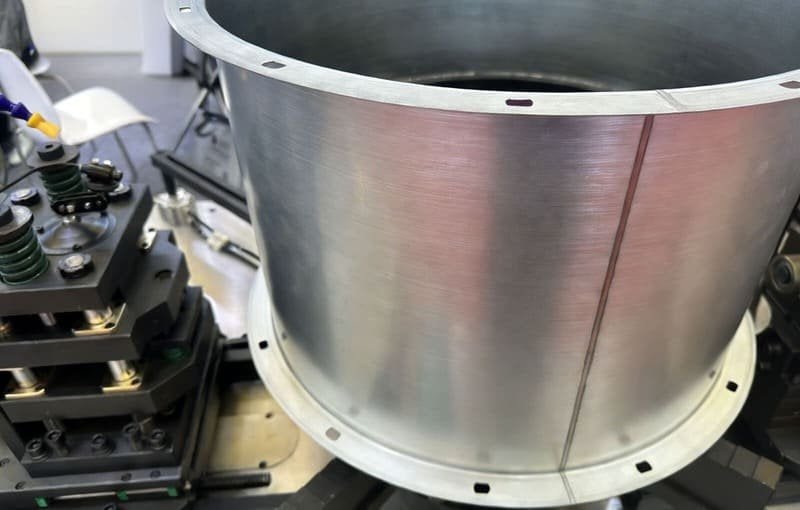

State-of-the-Art Manufacturing Facility

Our advanced production facility ensures the highest quality standards and precision engineering.

Advanced Manufacturing Capabilities

Our 15,000 sqm facility houses cutting-edge CNC machining centers, precision welding stations, and automated assembly lines, ensuring consistent quality and reliability in every machine we produce.

- ISO 9001:2015 certified quality management system

- Advanced CNC machining and precision fabrication

- Rigorous testing and quality assurance protocols

Trusted by Customers

Duct Work Discussion with Client

Shipment Preparation

Our Manufacturing Process

From initial design to final delivery, every step is meticulously planned and executed.

Design & Engineering

Custom solution development based on your requirements

Material Procurement

High-grade steel and components sourcing

Precision Manufacturing

CNC machining and expert fabrication

Quality Testing

Comprehensive performance validation

Global Delivery

Secure packaging and worldwide shipping

Dominate Your Ductwork Production

Dominate your production with the "CJ Three-Piece Suite," the #1 choice in the Chinese market. Our integrated sheet rolling, seam welding, and flanging solutions are the proven foundation for virtually all your ductwork scenarios.

Automated Production Lines

Complete integration of decoiling, leveling, forming, and welding into seamless high-output workflows.

Plate Rolling Machines

Precision sheet, plate bending equipment for various diameters and material thicknesses with exceptional accuracy.

Seam Welding Systems

Precision-engineered for flawless welds on materials as thin as 0.3mm. Our modular platforms offer ultimate versatility, allowing seamless switching between TIG, MIG, and Plasma processes.

Flanging & Punching

Streamline your production with integrated flanging and punching solutions, achieving superior forming quality and high-speed operation in one process.

Corrugated Pipe Systems

Specialized equipment for producing flexible ventilation pipes and corrugated duct components.

Tailored Engineering

Bespoke production line design and integration based on your specific factory layout and requirements.

Dynamic Solutions Showcase

Witness firsthand how our engineering transforms raw materials into finished products. A visual journey into efficiency and quality.

Sheet Rolling Machine

Manufacturing Process

Click to Load Video 2

Video will be embedded here

Flanging & Punching Machine

Equipment Showcase

Click to Load Video 3

YouTube Short will be embedded here

Seam Welding Machine

Factory Operations