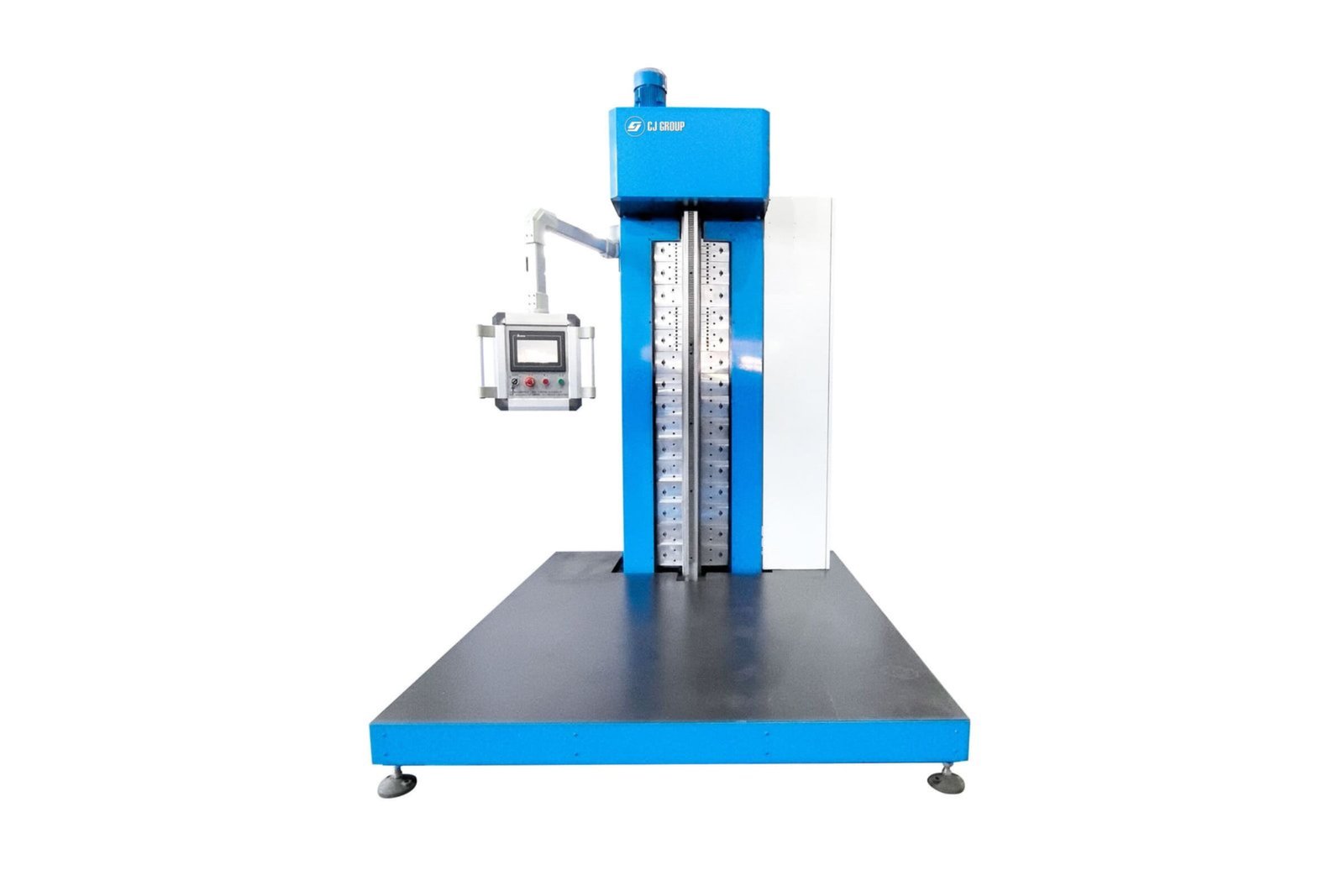

CSV Series: The End of Size and Shape Limitations

For decades, fabricators have been constrained by the physical limits of their equipment. The diameter of a tank, the shape of a duct—these were defined by the throat depth and clamping of a horizontal welder. Today, that changes. Introducing the CSV Series Vertical Seam Welder, a revolutionary, world-unique solution that fundamentally redefines what is possible in automated longitudinal welding.

Patented Advantages That Make the Impossible, Possible

-

1. Unlimited Diameter Capability (A Vertical Revolution)

This is the game-changer. By orienting the workpiece vertically and welding from top to bottom, the CSV series completely eliminates the horizontal constraints on diameter. Whether you are fabricating a 3-meter wide tank or a 10-meter wide silo, the CSV can handle it. Your only limit is your ceiling height, not your machine’s capacity. This opens up entirely new markets and project opportunities.

-

2. Unmatched Shape Versatility (Round, Square, Rectangular)

Why buy two machines when one can do it all? The CSV series is brilliantly engineered to weld not only traditional cylinders but also square and rectangular ducts with perfect corner-to-corner seams. This incredible flexibility makes it the single most valuable machine for HVAC contractors, electrical enclosure manufacturers, and custom architectural fabricators. Switch between shapes with minimal setup change, maximizing your workshop’s efficiency.

-

3. Signature 0.3mm Ultra-Precision Welding

Massive scale and shape versatility do not come at the expense of quality. The CSV series is built on the same foundation of precision as our other elite platforms. It delivers flawless, aesthetically perfect, and distortion-free welds on materials as thin as 0.3mm. The vertical, top-down process also uses gravity to its advantage, creating an exceptionally stable weld pool for unparalleled consistency.

More Reasons to Choose the CSV Series

- Reduced Floor Space: A vertical orientation means a significantly smaller footprint compared to a horizontal machine of similar length, freeing up valuable workshop space.

- Ergonomic & Safe: Easy loading of large workpieces at ground level and automated welding cycles keep your operators safe and reduce physical strain.

- Full Process Integration: Like all our platforms, the CSV is ready to be equipped with TIG, MIG/MAG, or PAW welding systems to suit your specific material and thickness requirements.

Technical Specifications Overview (CSV Series)

The CSV is engineered as a solution platform, configured for your unique needs.

| Model Series | CSV-1000 | CSV-1500 | CSV-2000 | CSV-3000+ (Custom Height) |

| Key Features | Vertical Top-Down Welding | Unlimited Diameter | Round & Square/Rectangular Capability |

| Weldable Workpiece Shapes | Cylinders, Cones, Square Ducts, Rectangular Ducts, Flat Sheets. |

| Weldable Thickness | 0.3mm to 6mm+ (Process and material dependent) |

| Weldable Diameter | Effectively Unlimited |

| Effective Welding Height | Up to 3000mm or more (Customizable to your needs) |

Applications Without Limits

The CSV series is the ultimate tool for visionary fabricators in industries such as:

- Large-Scale Storage: Silos, large-diameter tanks, industrial vessels.

- HVAC & Ducting: High-volume production of both round and rectangular ductwork.

- Architectural Fabrication: Custom columns, large decorative metalwork, complex structures.

- Electrical & Industrial Enclosures: Tall, rectangular cabinets and chassis.

Stop Saying “We Can’t.” Start Asking “How Big?”

The CSV Series Vertical Seam Welder is more than a machine; it’s a competitive advantage that unlocks your company’s potential. Bid on larger projects, diversify your offerings, and deliver unparalleled quality. Contact us to discover how the CSV can transform your business.